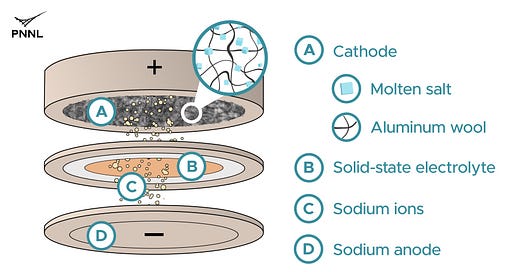

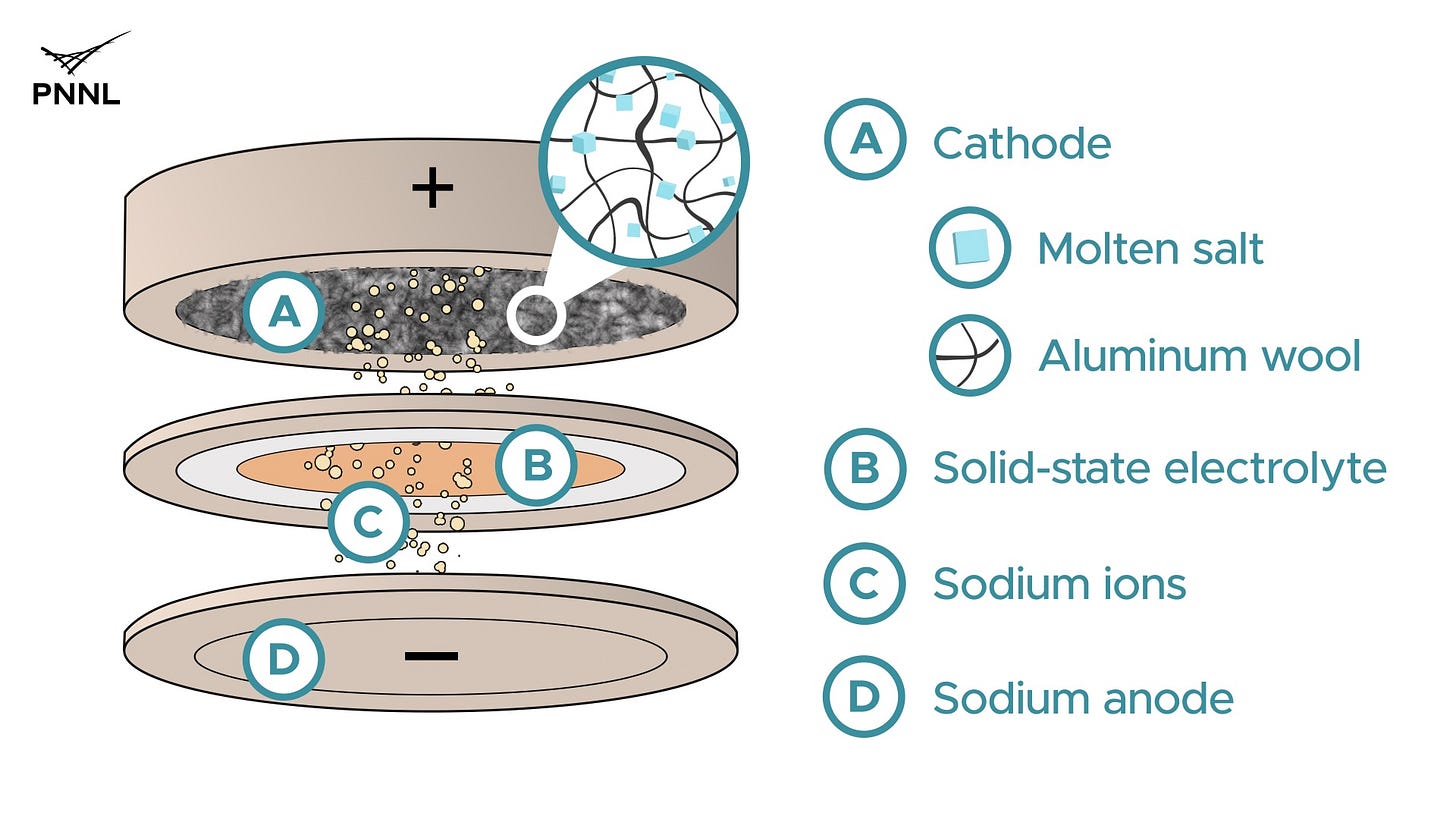

The Pacific Northwest National Laboratory (PNNL) recently released details of a new Sodium Ion (Na-ion) battery formulation. Predicting successful batteries technologies is seemingly a fools errand, with the sheer volume of ‘break-throughs’ and technologies being announced on a regular basis. A list which includes Sodium Ion, Iron based, Zinc based, Lithium Sulphur, Lithium Air and Silicon anodes. Where this new battery formulation distinguishes itself however is the use of Earth-abundant materials needed in its production; one comprised of sodium salts and aluminium wool, a bi-product of aluminium manufacturing. This means the cost of entry is significantly reduced, while also greatly democratising the technology, and thus allowing other nations to emulate.

While the technology is not commercially available yet, the inclusion of commercial/production companies (in this case Adena), is encouraging and hopefully means that a swift route to market will be possible.

Sodium Ion (Na-ion) batteries have traditionally operated within a density of about 70–160 Wh/kg. This level of energy density is not suitable for certain applications (such as EVs), as this technology has about 1/3 the energy density of Lithium Ion batteries (which operate at around 150–275Wh/kg). Where these inherent feature advantages lend themselves well, is larger scale applications (such as buildings) or industrial scale energy storage facilities (meant to bridge those times where renewable energy is not flowing).

Several years on from the Stet article on battery technology (issue 015), the battery alchemy space does not look any less active, although we are still short of a blue LED breakthrough. We are however seemingly getting closer to several new solutions that would allow us to reduce the carbon intensive energy gap.